Proof of Feasibility for Milling Extremely Deep Ribs (1.2 x 75 mm) with Modular Tools

The requirement was the manufacturing of an electrode with extremely filigree ribs (1.2 mm width at 75 mm height, 1° draft). This geometry resulted in a highly unstable cross-section. Due to the acute risk of breakage and the tendency towards vibration, machinability was considered critical. The goal was the pure verification of the technical feasibility of a stable machining process free of chatter marks.

The challenge consisted of controlling the cutting forces in such a way that neither component deflection nor vibrations occurred.

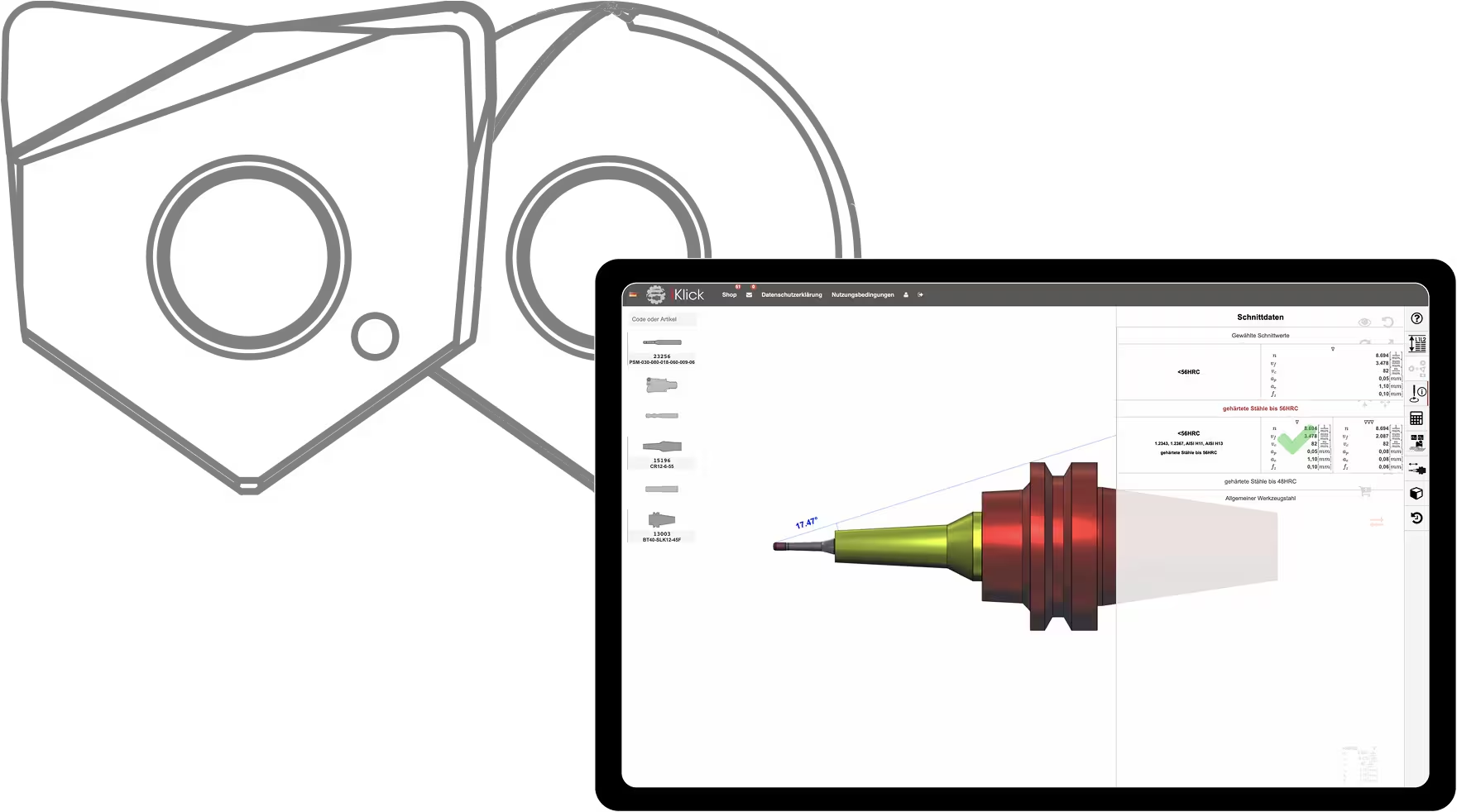

For this, we relied on modular tools with specifically designed, sharp cutting geometries. We synchronized this hardware with a CAM strategy that systematically keeps the mechanical load on the structure low through small step-downs and constant engagement conditions. We validated this **technology data** directly on the component to verify feasibility in a real-world scenario.

Validation in the technical center confirmed process stability. Through the defined alignment of tool and strategy, the geometric integrity of the 80 mm high ribs could be fully preserved.

The process produced no visible chatter marks or surface imperfections. Thus, technical proof has been provided that even such unstable geometries can be milled reliably and reproducibly through precise process control without component breakage occurring.

Contribution to the solution development of this project

Are you interested in the technical background of this solution? For detailed information, simply contact your personal contact person or send us a request. We are happy to answer any questions and look forward to the exchange.

Similar projects

Further applications

Aura Tools GmbH

Raiffeisenstraße 8

35236 Breidenbach

+49 6465 911 194 0

kontakt(at)aura-tools.de

iklick.aura.tools