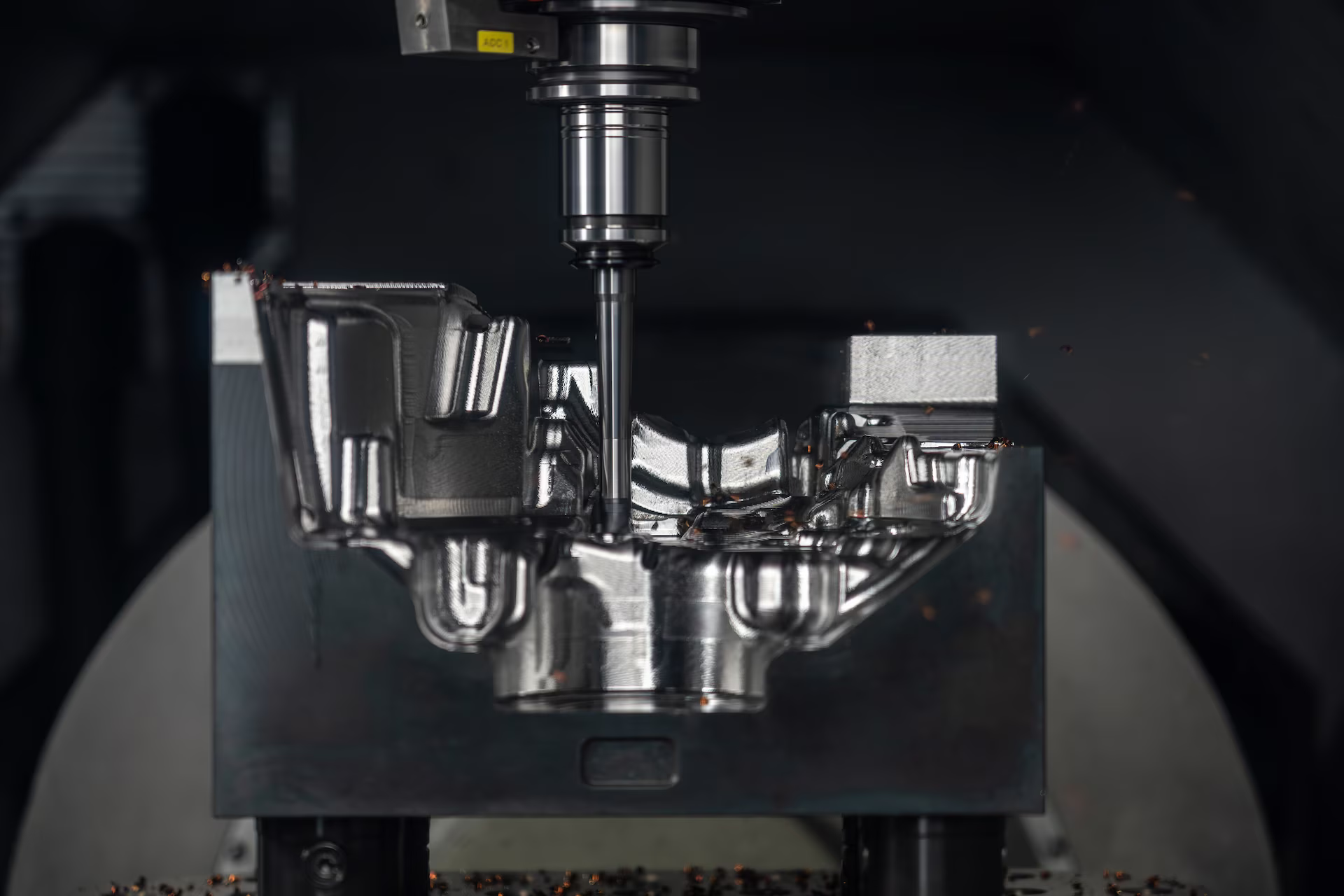

In the machining of smaller geometries (Ø 10–16 mm), manufacturers have often had to choose between the precision of solid carbide and the flexibility of indexable inserts. The ATF system was developed to resolve this trade-off. It positions itself as a differentiated alternative that combines process stability with an attractive ROI (Return on Investment).

A central focus is placed on the significant simplification of setup processes. The modular interface allows for substantially faster and safer handling compared to small-scale indexable insert systems. At the same time, we achieve an accuracy that exceeds the performance of conventional indexable insert solutions and comes close to that of monolithic tools.

Technically, the system is designed for high-feed roughing and rest roughing operations. It covers a broad material spectrum (ISO P, K, and H) and operates with process reliability in hardnesses up to 52 HRC. Through combination with variable screw-in extensions, various working depths can be realized. Thus, the ATF-System offers an optimized technical compromise between the stability of solid carbide and the cost-efficiency of modular systems.

Our Technical Sales and Application Engineering teams will gladly support you in designing the appropriate strategy and providing validated technology data for your production.

Would you like to learn more about the ATF system?

Do you want to know if the ATF system can make your existing processes more efficient? For a personal assessment and technical details, please contact your representative in technical sales or contact us directly at headquarters.

Similar projects

Further applications

Aura Tools GmbH

Raiffeisenstraße 8

35236 Breidenbach

+49 6465 911 194 0

kontakt(at)aura-tools.de

iklick.aura.tools