Process-reliable roughing in hardened tool steel

Manufacturing a bending jaw previously required an external hardening process, which extended the component's lead time. To eliminate this logistical interruption, machining was to be performed directly in the hardened state. The central challenge lay in process reliability: A stable, unmanned roughing operation lasting over 60 minutes was previously considered a technical risk by the partner and prevented autonomous production.

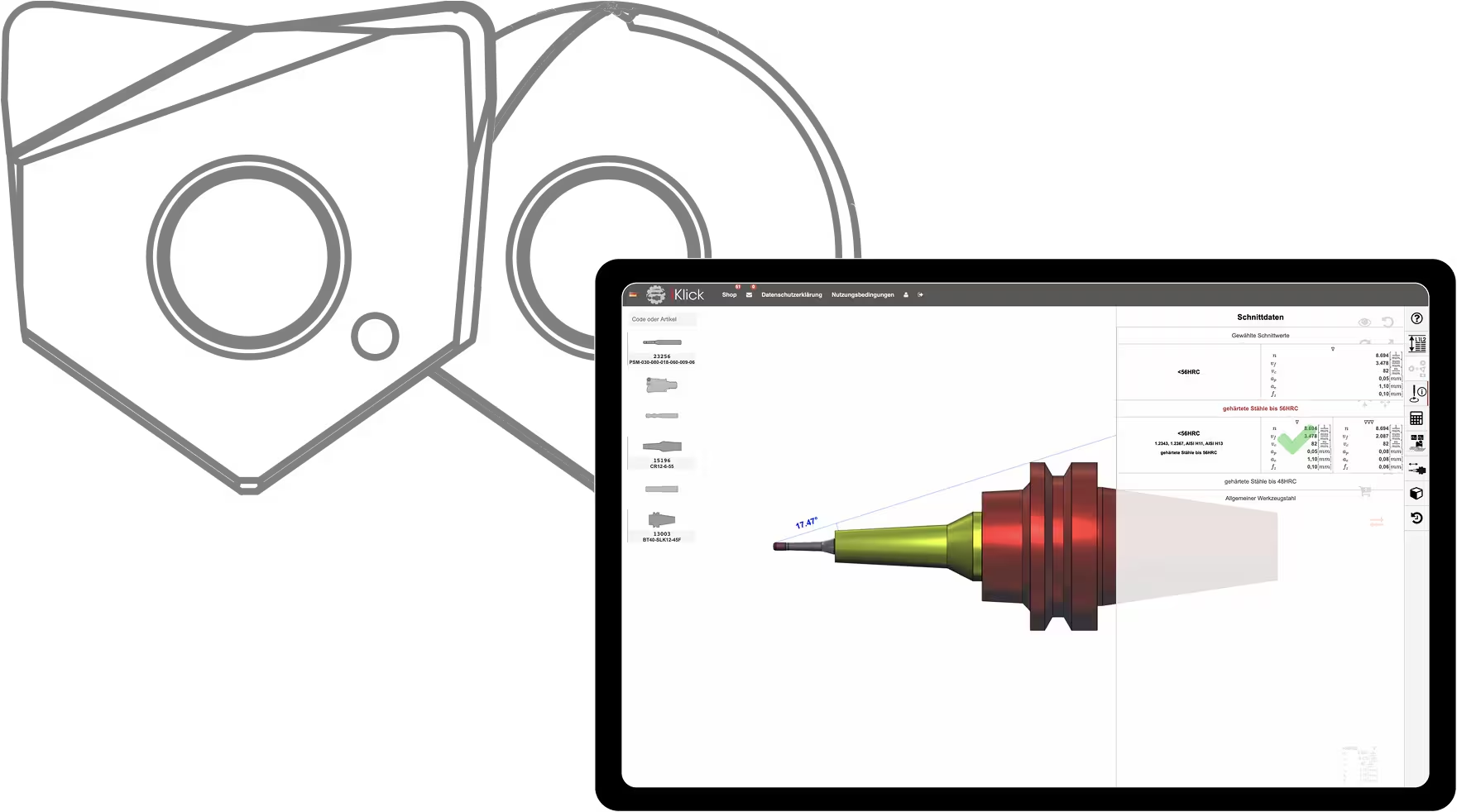

Since the partner classified the risk of an autonomous roughing process as critical due to a lack of empirical data, our focus was on validating tool life. Our approach was based on the assessment that with the correct geometry of the SHR family, hardened material can be roughed with process reliability over the target tool life.

We defined a machining strategy that makes mechanical loads controllable. To minimize risk, we first validated the process digitally using CAM simulation. Subsequently, the parameters were transferred to the machine, accompanied by our application engineering team for the fine-tuning of the cutting data on site.

Validation on the machine confirmed process stability. The required autonomous continuous operation of over 60 minutes is now realized reliably and reproducibly. We handed over the validated cutting data to the partner, enabling them to now perform hard machining even unattended.

By milling directly in the hardened material, the logistical effort of external heat treatment is completely eliminated. This results in an effective reduction of component lead time. With this optimized process, the manufacturer gains significant flexibility and can realize rush orders much more economically.

Contribution to the solution development of this project

Are you interested in the technical background of this solution? For detailed information, simply contact your personal contact person or send us a request. We are happy to answer any questions and look forward to the exchange.

Similar projects

Further applications

Aura Tools GmbH

Raiffeisenstraße 8

35236 Breidenbach

+49 6465 911 194 0

kontakt(at)aura-tools.de

iklick.aura.tools