Precise 5-axis simultaneous machining in hardened tool steel (60 HRC)

Manufacturing a mold insert made of HWS Premium (60 HRC) required a form tolerance of ± 0.0075 mm. The previous 3-axis strategy caused hundreds of hours of production time and still missed the required precision due to tool wear. The goal was to establish a stable 5-axis simultaneous machining process that achieves the accuracy with process reliability.

Our analysis of the existing process revealed the core problem: Due to the enormous runtimes involved in 3-axis raster milling, progressive wear led to dimensional deviations, particularly in the lower area of the dome structures. Our thesis was that this geometry could be machined much more precisely and economically using a 5-axis simultaneous strategy (flank milling) with endmills.

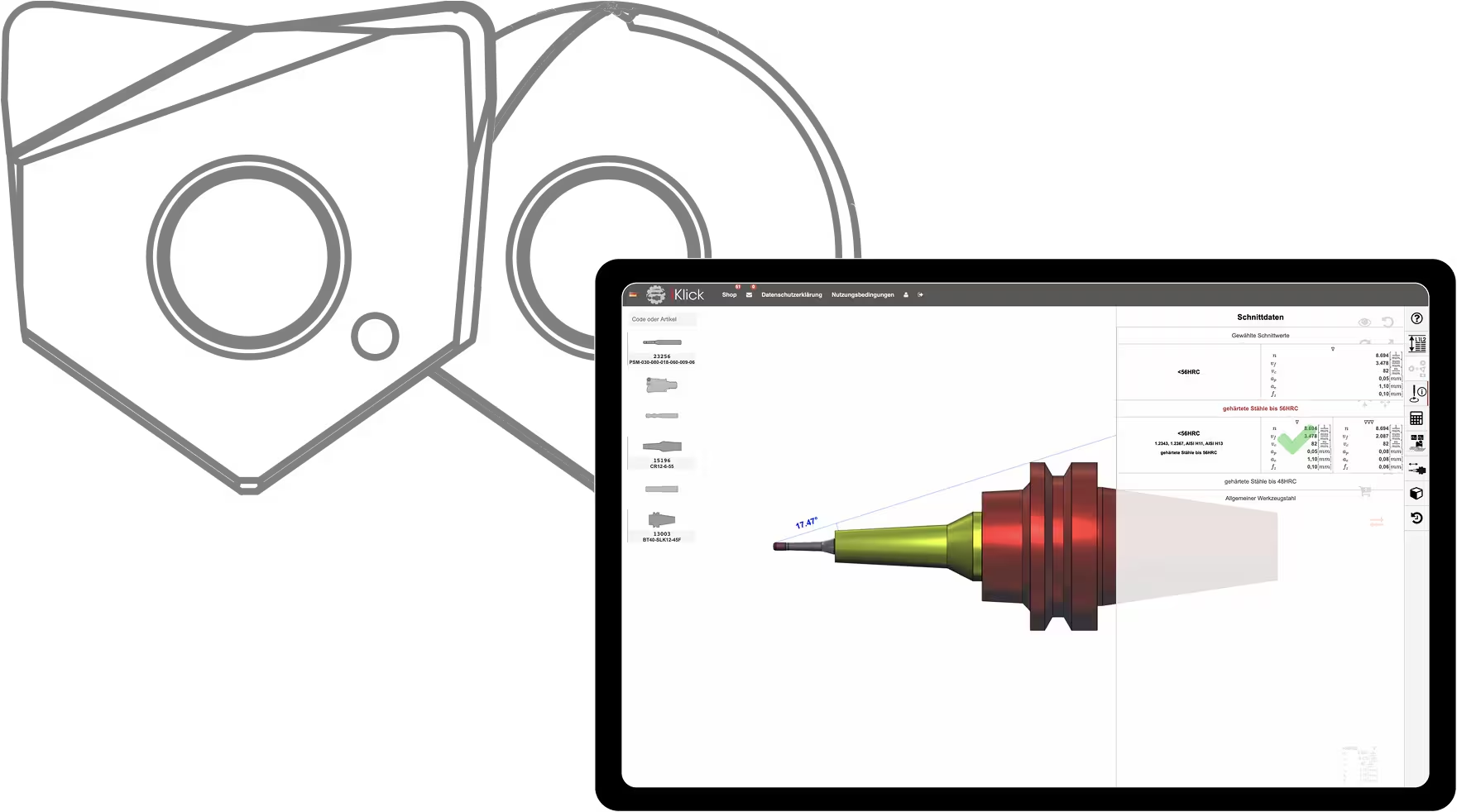

We first checked feasibility digitally and simulated the process in the CAM system to define collision freedom and tilt angles. For roughing directly in the hardened material, we designed a strategy using tools from the SHR and 4HQC family. The goal was to optimize the **technology data** so that a tool life of over 60 minutes could be realized despite the hardness of 60 HRC.

Validation directly on the partner's machine was successful. Roughing in the hardened material runs stably with a tool life of over 60 minutes. For the final finishing operation, we also use the 4HQC family in a flank milling process.

The result is a reproducible production process that reliably maintains the tight tolerances of ± 0.0075 mm. By switching from raster steps to simultaneous machining, production time was drastically reduced. We methodically enabled the partner on-site to apply this CAM strategy independently, allowing them to now realize complex geometries in HWS process-reliably and economically.

Contribution to the solution development of this project

Are you interested in the technical background of this solution? For detailed information, simply contact your personal contact person or send us a request. We are happy to answer any questions and look forward to the exchange.

Similar projects

Further applications

Aura Tools GmbH

Raiffeisenstraße 8

35236 Breidenbach

+49 6465 911 194 0

kontakt(at)aura-tools.de

iklick.aura.tools