The Intelligent Complement: Interaction between Solid Carbide Tools and Modular Head Systems in Mold Making

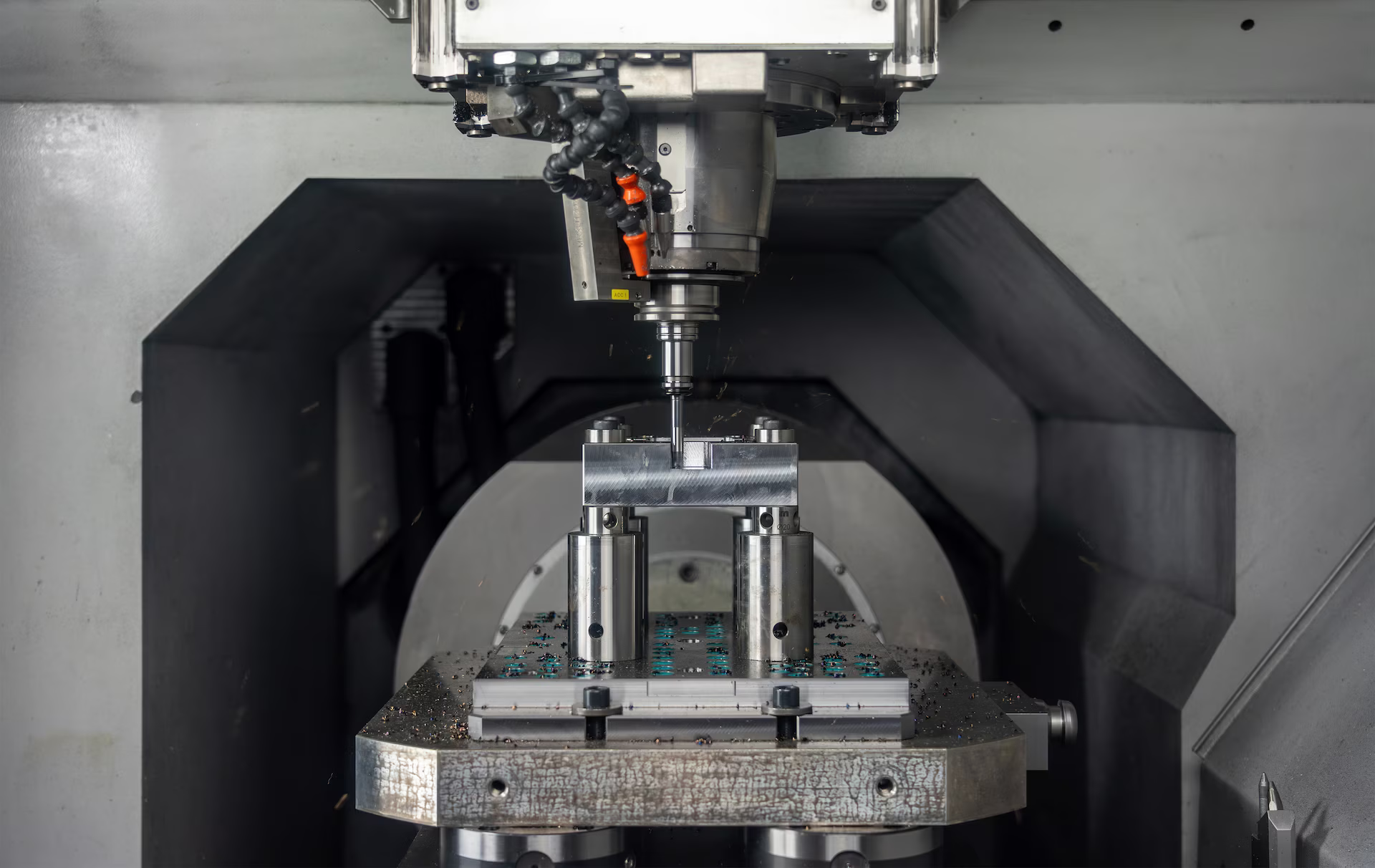

An injection mold maker produces small to medium-sized molds and the corresponding inserts from 1.2311 tool steel on a daily basis. The roughing of pockets, bosses, and slots is part of the standard process. Previously, monolithic solid carbide tools in diameters of 10 mm and 12 mm were used for this. The challenges were the rigid tool lengths in deep cavities. The goal was to increase production flexibility while maintaining process stability.

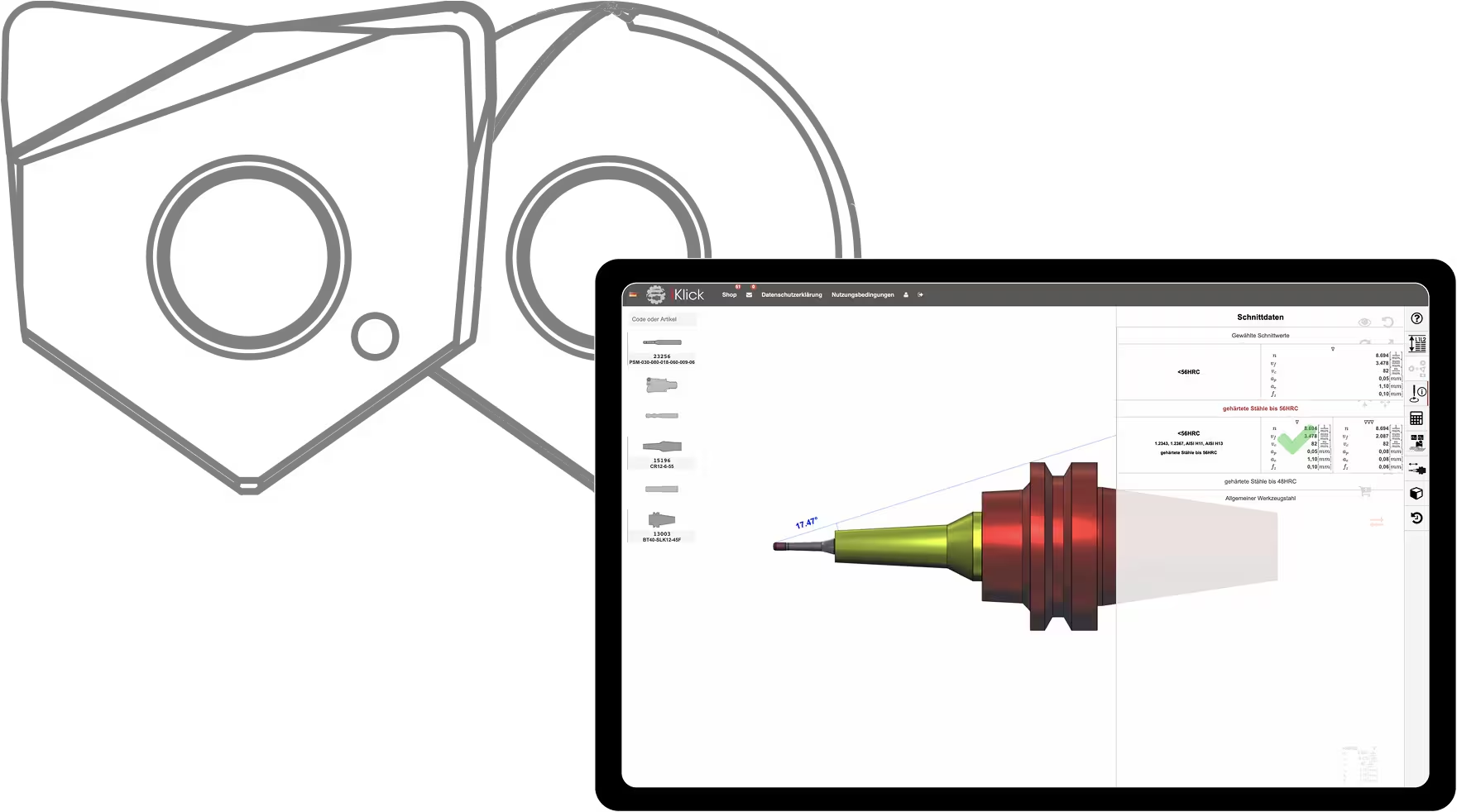

In the diameter range of 10–16 mm, long monolithic tools are powerful but very cost-intensive. Indexable inserts, on the other hand, are economical but offer poor handling due to their small size. The modular ATF system resolves this dilemma: Our thesis was that it delivers the technical performance of solid carbide but reduces costs and setup times.

The field test confirmed identical cutting data and tool life compared to the monolithic variant. The decisive gain lies in economic efficiency through the modularity of the tool. The system now universally covers 2.5D and 3D operations, complementing machining with monolithic tools.

Contribution to the solution development of this project

Are you interested in the technical background of this solution? For detailed information, simply contact your personal contact person or send us a request. We are happy to answer any questions and look forward to the exchange.

Similar projects

Further applications

Aura Tools GmbH

Raiffeisenstraße 8

35236 Breidenbach

+49 6465 911 194 0

kontakt(at)aura-tools.de

iklick.aura.tools