Process-reliable hard machining of deep ribs with tools > 10× D

When manufacturing complex components, our partner regularly encountered a self-imposed limit: As soon as the required milling depth exceeded ten times the tool diameter (10×D), the process was classified as unstable. To maintain the required tolerances of ± 0.05 mm without surface defects and to minimize the risk of scrap, production switched to sinker EDM for these deep rib areas (75 mm). However, this break in technology interrupted the flow, increased setup times, and created dependencies on external service providers. The goal was to overcome this hurdle and establish a pure milling strategy.

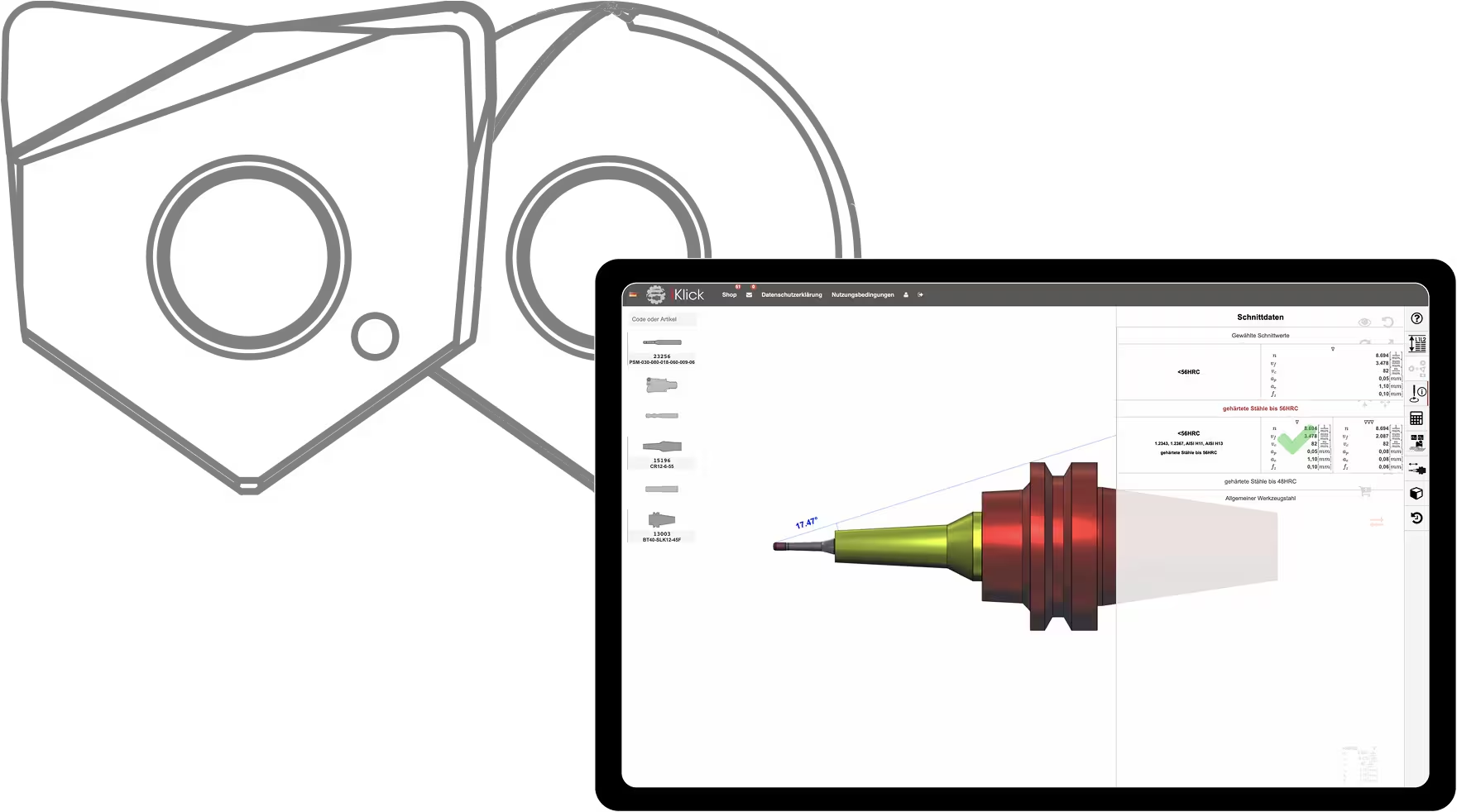

Our approach was based on the technical assessment that the deep areas (75 mm with 1.7° draft) can be machined with process reliability in hardened material even beyond 10×D using modern tool geometries - provided the cutting data and strategy are correct.

Since our portfolio covers these lengths as standard, we checked feasibility directly on the component geometry. While many areas appeared uncritical, we identified a specific zone that required special consideration.

For verification, we simulated the process in critical zones through real milling tests in our application engineering center. In doing so, we defined exact technology data and strategies that minimize vibrations and ensure stable chip evacuation. Parallel to this, we transparently compared the determined cycle times and tool costs against the expenses of electrode manufacturing.

Validation in our technical center confirmed that machining is not only feasible but also reliably and reproducibly possible under serial production conditions. We transferred the determined technology data and process conditions directly to the partner's production, enabling them to now machine even deep cavities with process reliability.

By switching to complete milling, the time-consuming design and programming efforts for electrodes as well as setup times for EDM are completely eliminated. The manufacturer benefits from a significantly accelerated throughput, as waiting times for downstream processes are removed. With this expanded know-how, the entire production sequence now takes place on the milling machine, allowing machine utilization to be managed more flexibly and the component to be realized much more economically.

Contribution to the solution development of this project

Are you interested in the technical background of this solution? For detailed information, simply contact your personal contact person or send us a request. We are happy to answer any questions and look forward to the exchange.

Similar projects

Further applications

Aura Tools GmbH

Raiffeisenstraße 8

35236 Breidenbach

+49 6465 911 194 0

kontakt(at)aura-tools.de

iklick.aura.tools